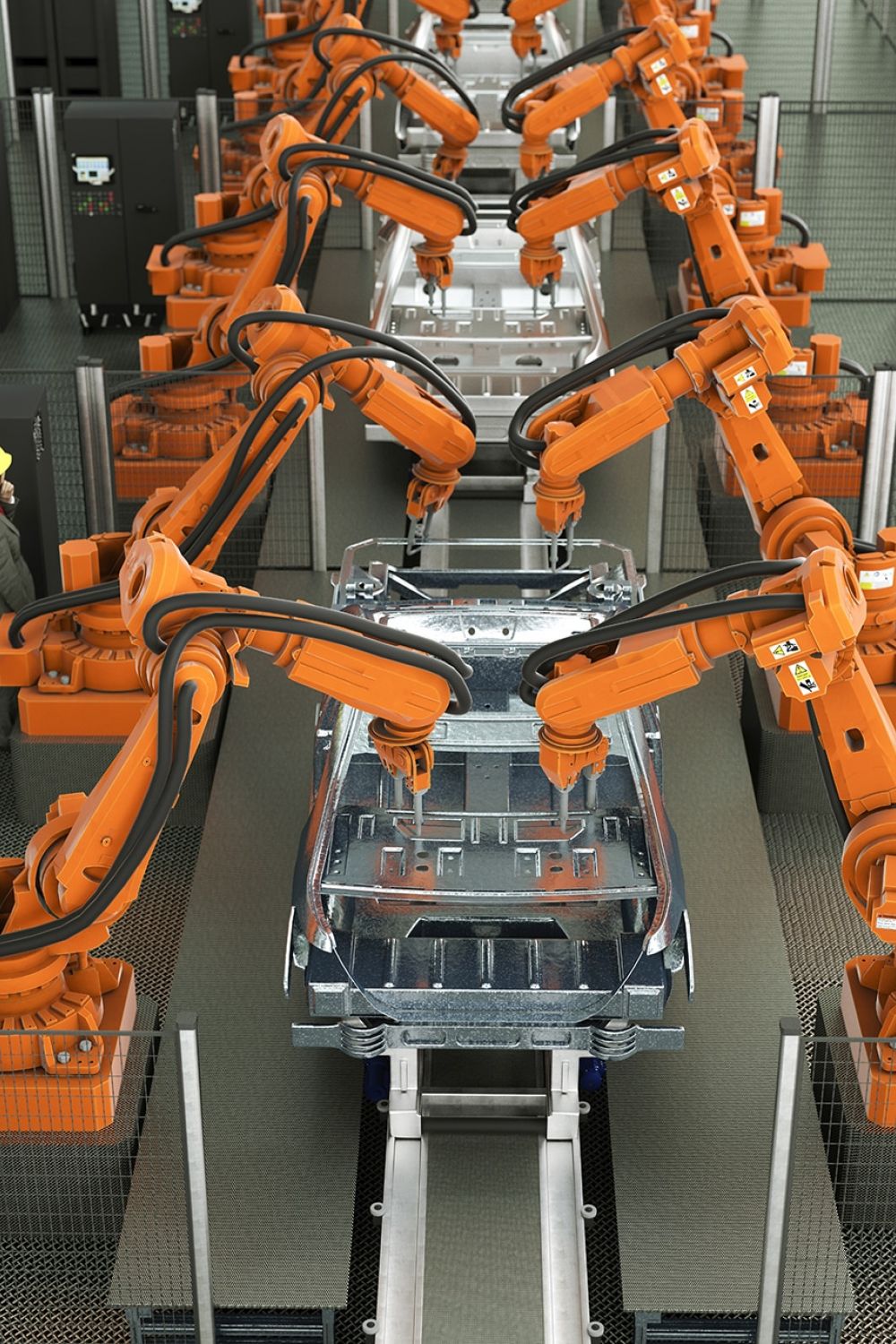

Manufacturing

Resilient IT Infrastructure for Modern Manufacturing

Ferroque empowers manufacturers with secure endpoints and digital workspaces, high-performance networking, and scalable infrastructure. We keep production lines, warehouses, and offices connected, efficient, and protected.

Technology for the Factory Floor and Beyond

Manufacturers face complex technology challenges: enabling secure access across plant floors and offices, integrating legacy systems with modern infrastructure, supporting diverse endpoints in rugged environments, optimizing production workflows, and securing operational data across distributed facilities.

We understand the unique pressures of manufacturing IT, where downtime is costly, environments are harsh, and legacy systems can’t always be replaced overnight. Ferroque delivers infrastructure that’s resilient, scalable, and designed to bridge the gap between old and new.

Manufacturing IT Challenges We Can Solve Together

Legacy systems with limited cloud compatibility

Secure access across plant floors and remote offices

Compliance with strict data security and operational standards

Lack of centralized visibility across facilities and operations

Complex endpoint management in industrial settings

Ferroque Bridges the Divide

in Manufacturing IT

-

Network Resiliency

Our network solutions for manufacturing environments ensure reliable application and network connectivity across factories, warehouses, and remote sites. We implement load balancing and failover strategies to minimize downtime and maintain operational continuity in even the harshest conditions.

-

Workspace Modernization

We deploy secure digital workspaces and endpoint solutions tailored for frontline, engineering, and corporate staff. Using VDI, thin client, centralized digital employee experience tooling, and network security technologies, we simplify endpoint management while ensuring seamless access to apps and data across production and administrative environments.

-

Operational Visibility

We enable centralized control and monitoring across all facilities, connecting OT and IT environments. Our solutions deliver actionable insights into system performance, user activity, user experience, and network behaviour to improve uptime and operational efficiency.

-

Regulatory Compliance

We help manufacturers meet strict industry regulations with hardened infrastructure, granular access controls, audit-ready reporting, and data protection aligned with standards like ISO, NIST, and industry-specific mandates.

-

Industrial-Grade Security

Our layered security approach protects manufacturing systems against both external threats and internal risks. With zero trust architecture, microsegmentation, and secure remote access, we defend operational data and production assets across all sites.

The Ferroque Edge in Manufacturing IT

Ferroque solves complex IT problems in the manufacturing industry so you can focus on what matters most: production, quality, and uptime.

Driving operational efficiency and modernizing legacy infrastructure is what sets us apart.

We specialize in building resilient, secure IT environments that integrate seamlessly with existing production systems. Our tailored approach helps manufacturers bridge the gap between aging industrial systems and modern digital infrastructure, delivering scalable, high-performance solutions.

We understand the demands of manufacturing, where downtime is costly, environments are rugged, and visibility across facilities is critical. Ferroque’s deep expertise in secure access, endpoint management, and network connectivity & performance makes us a trusted partner for manufacturers aiming to stay competitive, secure, and agile.

Professional and Managed Services

Built for the Manufacturing Industry

Let us know your goals, and we’ll adapt our approach to meet your specific manufacturing requirements.

Our Manufacturing Experience

Projects

Manufacturing engagements we’ve delivered with to improve security, agility, and availability

Global Firms

Global manufacturing leaders we’ve worked with across complex, multi-site environments

Highly Regulated Clients

Enabling enterprise manufacturers to scale and secure operations across regions and facilities

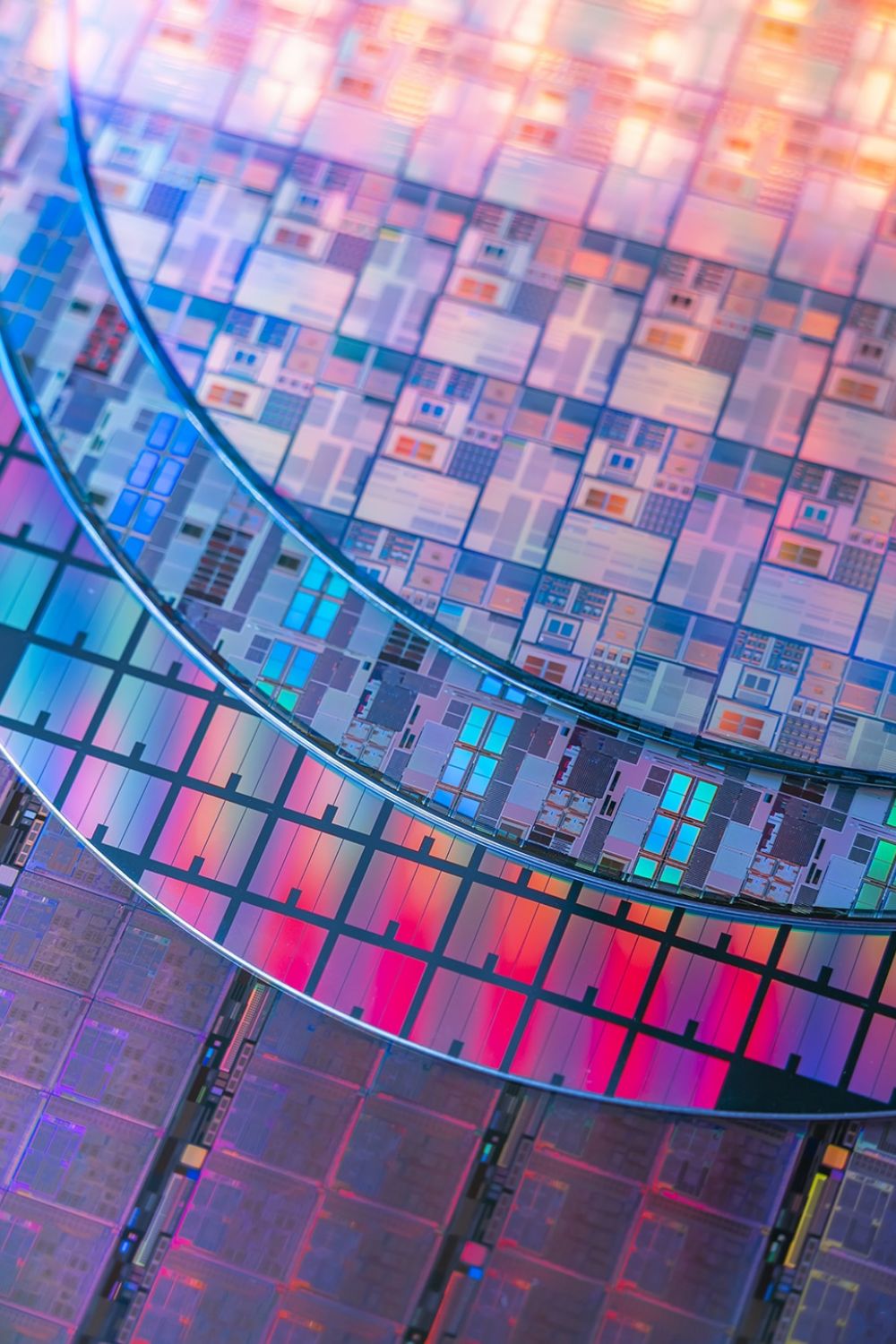

Discover Our Expertise in

End-User Infrastructure

FAQs About Ferroque and Manufacturing

Have a question we didn’t answer? Contact us!

Ferroque designs and deploys secure modern workspaces with identity-based access controls, VDI, enterprise browsers, and SASE frameworks, ensuring reliable and secure connectivity for users across all manufacturing environments.

Ferroque has worked with manufacturers in aerospace, chemicals, and industrial sectors, helping them meet compliance requirements like NIST, ISO, and sector-specific standards while maintaining performance and visibility.

We craft zero trust architectures using SASE, VDI, enterprise browser, and endpoint management solutions, and use microsegmentation to isolate production assets. We also integrate secure access brokers, real-time monitoring, and automated policy enforcement tied to user identity and device posture which are critical in regulated environments like aerospace, pharma, and chemical processing.

Absolutely. Whether through staff augmentation, collaborative management, or our SOC2 compliant fully managed services, we have options to relieve your pain points and enable organizations to stabilize, optimize, and scale.

Ferroque has conducted over 75 health checks, infrastructure assessments, and security assessments on Citrix, VMware, Microsoft technologies, NetScalers, and major hypervisor and public clouds. Audits are one of our greatest strengths, bringing to bear decades of field experience and our knowledge of ever-evolving vendor best practices to generate actionable insights for customers to resolve or avoid serious issues. We’ve developed some of the most extensive assessment methodologies in our field and they’re continually updated, making annual health checks a common request.

Explore Our Latest Articles

Get in touch

Want to connect with experts who can take your Manufacturing operations to the next level?

"*" indicates required fields